2021 edition

2018 edition

2015 edition

2012 edition

2012 IRC

R905.2 Asphalt shingles. The installation of asphalt shingles shall comply with the provisions of this section.

. . . .

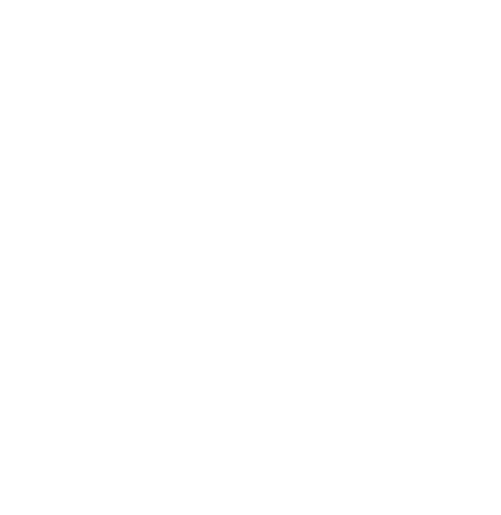

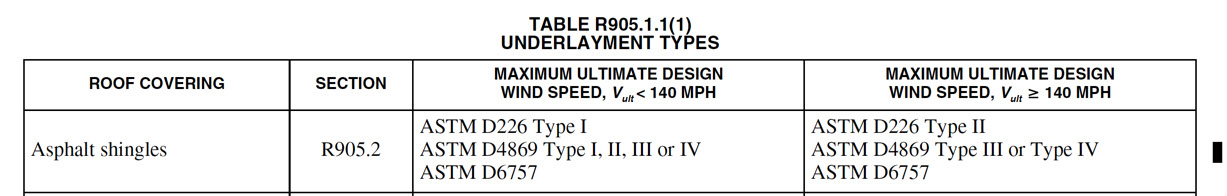

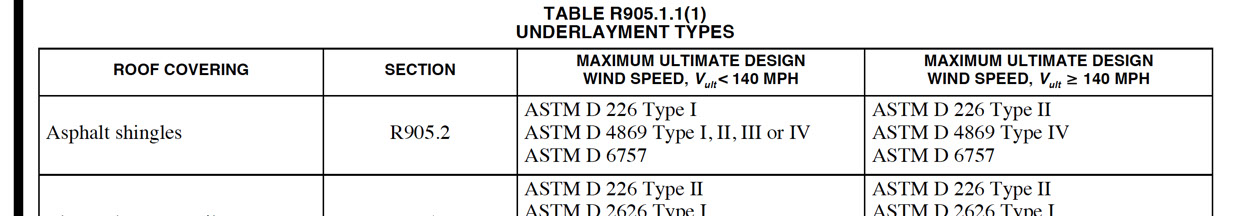

R905.2.3 Underlayment. Unless otherwise noted, required underlayment shall conform to ASTM D 226 Type I, ASTM D 4869 Type I, or ASTM D 6757. Self-adhering polymer modified bitumen sheet shall comply with ASTM D 1970.

. . . .

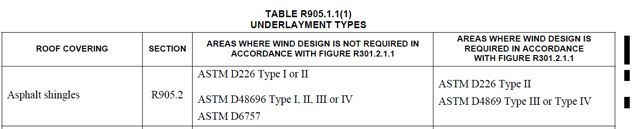

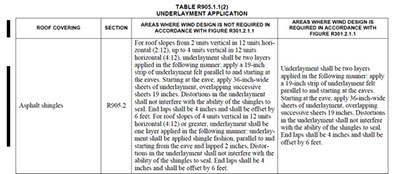

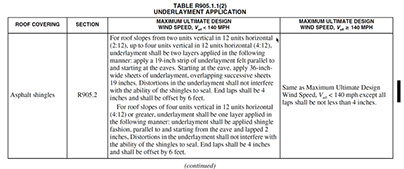

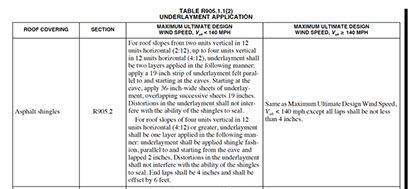

R905.2.7 Underlayment application. For roof slopes from two units vertical in 12 units horizontal (17-percent slope), up to four units vertical in 12 units horizontal (33- percent slope), underlayment shall be two layers applied in the following manner. Apply a 19-inch (483 mm) strip of underlayment felt parallel to and starting at the eaves, fastened sufficiently to hold in place. Starting at the eave, apply 36-inch-wide (914 mm) sheets of underlayment, overlapping successive sheets 19 inches (483 mm), and fastened sufficiently to hold in place. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. For roof slopes of four units vertical in 12 units horizontal (33-percent slope) or greater, underlayment shall be one layer applied in the following manner. Underlayment shall be applied shingle fashion, parallel to and starting from the eave and lapped 2 inches (51 mm), fastened sufficiently to hold in place. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. End laps shall be offset by 6 feet (1829 mm).

R905.2.7.1 Ice barrier. In areas where there has been a history of ice forming along the eaves causing a backup of water as designated in Table R301.2(1), an ice barrier that consists of a least two layers of underlayment cemented together or of a self-adhering polymer modified bitumen sheet, shall be used in lieu of normal underlayment and extend from the lowest edges of all roof surfaces to a point at least 24 inches (610 mm) inside the exterior wall line of the building.

Exception: Detached accessory structures that contain no conditioned floor area.

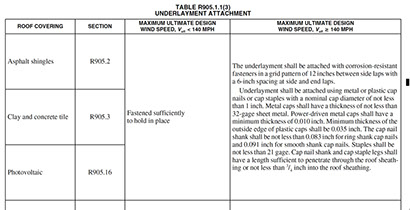

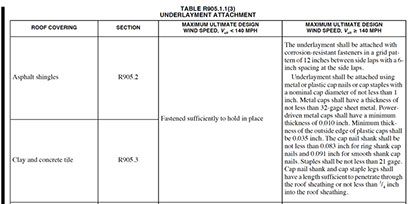

R905.2.7.2 Underlayment and high winds. Underlayment applied in areas subject to high winds [above 110 mph (49 m/s) in accordance with Figure R301.2(4)A] shall be applied with corrosion-resistant fasteners in accordance with manufacturer’s installation instructions. Fasteners are to be applied along the overlap not farther apart than 36 inches (914 mm) on center. Underlayment installed where the basic wind speed equals or exceeds 120 mph (54 m/s) shall comply with ASTM D 226 Type II, ASTM D 4869 Type IV, or ASTM D 6757. The underlayment shall be attached in a grid pattern of 12 inches (305 mm) between side laps with a 6-inch (152 mm) spacing at the side laps. Underlayment shall be applied in accordance with Section R905.2.7 except all laps shall be a minimum of 4 inches (102 mm). Underlayment shall be attached using metal or plastic cap nails with a head diameter of not less than 1 inch (25.4 mm) with a thickness of at least 32-gauge sheet metal. The cap-nail shank shall be a minimum of 12 gauge (0.105 inches) with a length to penetrate through the roof sheathing or a minimum of 3 /4 inch (19 mm) into the roof sheathing.

Exception: As an alternative, adhered underlayment complying with ASTM D 1970 shall be permitted.

2009 edition

R905.2 Asphalt shingles. The installation of asphalt shingles shall comply with the provisions of this section.

. . . .

R905.2.3 Underlayment. Unless otherwise noted, required underlayment shall conform to ASTM D 226 Type I, ASTM D 4869 Type I, or ASTM D 6757. Self-adhering polymer modified bitumen sheet shall comply with ASTM D 1970.

. . . .

R905.2.7 Underlayment application. For roof slopes from two units vertical in 12 units horizontal (17-percent slope), up to four units vertical in 12 units horizontal (33- percent slope), underlayment shall be two layers applied in the following manner. Apply a 19-inch (483 mm) strip of underlayment felt parallel to and starting at the eaves, fastened sufficiently to hold in place. Starting at the eave, apply 36-inch-wide (914 mm) sheets of underlayment, overlapping successive sheets 19 inches (483 mm), and fastened sufficiently to hold in place. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. For roof slopes of four units vertical in 12 units horizontal (33-percent slope) or greater, underlayment shall be one layer applied in the following manner. Underlayment shall be applied shingle fashion, parallel to and starting from the eave and lapped 2 inches (51 mm), fastened sufficiently to hold in place. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. End laps shall be offset by 6 feet (1829 mm).

R905.2.7.1 Ice barrier. In areas where there has been a history of ice forming along the eaves causing a backup of water as designated in Table R301.2(1), an ice barrier that consists of a least two layers of underlayment cemented together or of a self-adhering polymer modified bitumen sheet, shall be used in lieu of normal underlayment and extend from the lowest edges of all roof surfaces to a point at least 24 inches (610 mm) inside the exterior wall line of the building.

Exception: Detached accessory structures that contain no conditioned floor area.

R905.2.7.2 Underlayment and high winds. Underlayment applied in areas subject to high winds [above 110 mph (49 m/s) in accordance with Figure R301.2(4)A] shall be applied with corrosion-resistant fasteners in accordance with manufacturer’s installation instructions. Fasteners are to be applied along the overlap not farther apart than 36 inches (914 mm) on center. Underlayment installed where the basic wind speed equals or exceeds 120 mph (54 m/s) shall comply with ASTM D 226 Type II, ASTM D 4869 Type IV, or ASTM D 6757. The underlayment shall be attached in a grid pattern of 12 inches (305 mm) between side laps with a 6-inch (152 mm) spacing at the side laps. Underlayment shall be applied in accordance with Section R905.2.7 except all laps shall be a minimum of 4 inches (102 mm). Underlayment shall be attached using metal or plastic cap nails with a head diameter of not less than 1 inch (25.4 mm) with a thickness of at least 32-gauge sheet metal. The cap-nail shank shall be a minimum of 12 gauge (0.105 inches) with a length to penetrate through the roof sheathing or a minimum of 3 /4 inch (19 mm) into the roof sheathing.

Exception: As an alternative, adhered underlayment complying with ASTM D 1970 shall be permitted.

2006 edition

R905.2 Asphalt shingles. The installation of asphalt shingles shall comply with the provisions of this section.

. . . .

R905.2.3 Underlayment. Unless otherwise noted, required underlayment shall conform to ASTM D 226 Type I, ASTM D 4869 Type I, or ASTM D 6757. Self-adhering polymer modified bitumen sheet shall comply with ASTM D 1970.

. . . .

R905.2.7 Underlayment application. For roof slopes from two units vertical in 12 units horizontal (17-percent slope), up to four units vertical in 12 units horizontal (33- percent slope), underlayment shall be two layers applied in the following manner. Apply a 19-inch (483 mm) strip of underlayment felt parallel to and starting at the eaves, fastened sufficiently to hold in place. Starting at the eave, apply 36-inch-wide (914 mm) sheets of underlayment, overlapping successive sheets 19 inches (483 mm), and fastened sufficiently to hold in place. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. For roof slopes of four units vertical in 12 units horizontal (33-percent slope) or greater, underlayment shall be one layer applied in the following manner. Underlayment shall be applied shingle fashion, parallel to and starting from the eave and lapped 2 inches (51 mm), fastened sufficiently to hold in place. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. End laps shall be offset by 6 feet (1829 mm).

R905.2.7.1 Ice barrier. In areas where there has been a history of ice forming along the eaves causing a backup of water as designated in Table R301.2(1), an ice barrier that consists of a least two layers of underlayment cemented together or of a self-adhering polymer modified bitumen sheet, shall be used in lieu of normal underlayment and extend from the lowest edges of all roof surfaces to a point at least 24 inches (610 mm) inside the exterior wall line of the building.

Exception: Detached accessory structures that contain no conditioned floor area.

R905.2.7.2 Underlayment and high winds. Underlayment applied in areas subject to high winds [above 110 mph (49 m/s) in accordance with Figure R301.2(4)A] shall be applied with corrosion-resistant fasteners in accordance with manufacturer’s installation instructions. Fasteners are to be applied along the overlap not farther apart than 36 inches (914 mm) on center. Underlayment installed where the basic wind speed equals or exceeds 120 mph (54 m/s) shall comply with ASTM D 226 Type II, ASTM D 4869 Type IV, or ASTM D 6757. The underlayment shall be attached in a grid pattern of 12 inches (305 mm) between side laps with a 6-inch (152 mm) spacing at the side laps. Underlayment shall be applied in accordance with Section R905.2.7 except all laps shall be a minimum of 4 inches (102 mm). Underlayment shall be attached using metal or plastic cap nails with a head diameter of not less than 1 inch (25.4 mm) with a thickness of at least 32-gauge sheet metal. The cap-nail shank shall be a minimum of 12 gauge (0.105 inches) with a length to penetrate through the roof sheathing or a minimum of 3 /4 inch (19 mm) into the roof sheathing.

Exception: As an alternative, adhered underlayment complying with ASTM D 1970 shall be permitted.

2003 edition

2003 IRC

R905.2.3 Underlayment. Unless otherwise noted, required underlayment shall conform with ASTM D 226, Type I, or ASTM D 4869, Type I. Self-adhering polymer modified bitumen sheet shall comply with ASTM D 1970.

. . .

R905.2.7 Underlayment application. For roof slopes from two units vertical in 12 units horizontal (17-percent slope), up to four units vertical in 12 units horizontal (33-percent slope), underlayment shall be two layers applied in the following manner. Apply a 19-inch (483mm) strip of underlayment felt parallel with and starting at the eaves, fastened sufficiently to hold in place. Starting at the eave, apply 36-inch-wide (914 mm) sheets of underlayment, overlap- ping successive sheets 19 inches (483 mm), and fastened sufficiently to hold in place. For roof slopes of four units vertical in 12 units horizontal (33-percent slope) or greater, underlayment shall be one layer applied in the following manner. Underlayment shall be applied shingle fashion, parallel to and starting from the eave and lapped 2 inches (51 mm), fastened sufficiently to hold in place. End laps shall be offset by 6 feet (1829 mm).

R905.2.7.1 Ice protection. In areas where the average daily temperature in January is 25 F (-4 C) or less or whenTableR301.2(1) criteria so designates, an ice barrier that consists of a least two layers of underlayment cemented together or of a self-adhering polymer modified bitumen sheet, shall be used in lieu of normal underlayment and extend from the eave’s edge to a point at least 24 inches (610 mm) inside the exterior wall line of the building.

Exception: Detached accessory structures that contain no conditioned floor area. R905.2.7.2 Underlayment and high wind. Underlayment applied in areas subject to high winds [greater than 110 mph (177km/h) per Figure R301.2(4)] shall be applied with corrosion-resistant fasteners in accordance with manufacturer’s installation instructions. Fasteners are to be applied along the overlap not farther apart than 36 inches (914 mm) on center.

2000 edition

2000 IRC

R905.2 Asphalt shingles. The installation of asphalt shingles shall comply with the provisions of this section.

. . . .

R905.2.3 Underlayment. Unless otherwise noted, required underlayment shall conform with ASTM D 226, Type I, or ASTM D 4869, Type I. Self-adhering polymer modified bitumen sheet shall comply with ASTM D 1970.

. . . .

R905.2. 7 Underlayment application. For roof slopes from two units vertical in 12 units horizontal (17-percent slope), up to four units vertical in 12 units horizontal (33-percent slope), underlayment shall be two layers applied in the following manner. Apply a 19-inch (483 mm) strip of underlayment felt parallel with and starting at the eaves, fastened sufficiently to hold in place. Starting at the eave, apply 36-inch-wide (914 mm) sheets of underlayment, overlap- ping successive sheets 19 inches (483 mm), and fastened e sufficiently to hold in place. For roof slopes of four units vertical in 12 units horizontal (33-percent slope) or greater, underlayment shall be one layer applied in the following manner. Underlayment shall be applied shingle fashion, parallel to and starting from the eave and lapped 2 inches (51 mm), fastened sufficiently to hold in place. End laps shall be offset by 6 feet (1829 mm).

R905.2.7.1 Ice protection. In areas where the average daily temperature in January is 25°F ( -4°C) or less, an ice barrier that consists of a least two layers of underlayment cemented together or of a self-adhering polymer modified bitumen sheet, shall be used in · lieu of normal underlayment and extend from the eave’s edge to a point at least 24 inches (610 mm) inside the exterior wall line of the building.

R905.2. 7.2 Underlayment and high wind. Underlayment applied in areas subject to high winds [greater than 110 mph (177kmlh) per Figure R301.2(4)] shall be applied with corrosion-resistant fasteners in accordance with manufacturer’s installation instructions. Fasteners are to be applied along the overlap not farther apart than 36 inches (914 mm) on center.